The Basic Support process areas address fundamental support functions that are used by all process areas. Although all Support process areas rely on the other process areas for input, the Basic Support process areas provide support

functions that also help implement several generic practices.

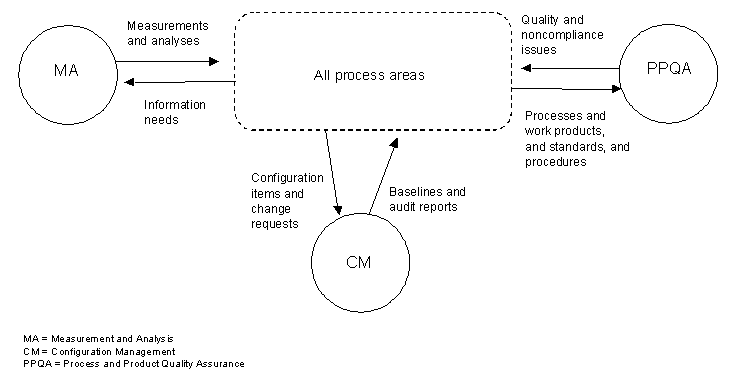

Figure 4.6 provides a bird’s-eye view of the interactions among the Basic Support process areas and with all other process areas.

Figure 4.6: Basic Support Process Areas

The Measurement and Analysis process area supports all process areas by providing specific practices that guide projects and organizations in aligning measurement needs and objectives with a measurement approach that will provide

objective results. These results can be used in making informed decisions and taking appropriate corrective actions.

The Process and Product Quality Assurance process area supports all process areas by providing specific practices for objectively evaluating performed processes, work products, and services against the applicable process

descriptions, standards, and procedures, and ensuring that any issues arising from these reviews are addressed. Process and Product Quality Assurance supports the delivery of high-quality products and services by providing the project staff and all

levels of managers with appropriate visibility into, and feedback on, the processes and associated work products throughout the life of the project.

The Configuration Management process area supports all process areas by establishing and maintaining the integrity of work products using configuration identification, configuration control, configuration status accounting, and

configuration audits. The work products placed under configuration management include the products that are delivered to the customer, designated internal work products, acquired products, tools, and other items that are used in creating and

describing these work products. Examples of work products that may be placed under configuration management include plans, process descriptions, requirements, design data, drawings, product specifications, code, compilers, product data files, and

product technical publications.